RH and Temperature Monitoring System

A reliable system that monitors and records relative humidity and temperature in real time. Ideal for cleanrooms, labs, and storage areas, it ensures environmental control through precise sensors, data logging, and alert notifications to maintain compliance and product quality.

Andon Board System at Trimline

The Andon Board System at the trimline is a real-time production monitoring and alert solution that displays output status, downtime events, and shift performance directly on the line. By providing operators and supervisors with instant visibility through boards, alarms, and signals, it ensures quick response to issues, minimizes delays, and helps maintain smooth and efficient operations along the trimline.

Production Progress Monitoring System

An integrated solution designed to track and display real-time production status across various stages of the manufacturing process. Through automated data collection and visualization, PPMS supports proactive decision-making, reduces downtime, and ensures that production targets and schedules are met.

Production of RFID Monitoring and Tracking System

The RFID Monitoring and Tracking System is a cutting-edge solution developed to enhance the efficiency, accuracy, and security of tracking assets, inventory, and personnel across various industries. Leveraging advanced Radio Frequency Identification (RFID) technology, this system provides a reliable way to automate monitoring processes, streamline operations, and access real-time data critical for decision-making.

Preventive Maintenance System

The Watsons Preventive Maintenance System (PMS) is a centralized platform designed to streamline and automate maintenance activities across Watsons facilities. It ensures equipment and assets are regularly serviced, minimizing downtime and extending their lifespan. The system allows scheduling of preventive maintenance tasks, tracking of work orders, and monitoring of spare parts and consumables. With real-time reporting and compliance tracking, Watsons PMS enhances operational efficiency, reduces costs, and supports a smooth, uninterrupted customer experience.

Computerized Maintenance Management System

A Computerized Maintenance Management System (CMMS) is a software solution designed to streamline maintenance operations by centralizing data, automating work orders, and tracking assets, equipment, and inventory. It helps organizations schedule preventive maintenance, monitor equipment performance, reduce downtime, and optimize resource utilization. By providing real-time visibility and reporting, a CMMS improves efficiency, extends asset life, and supports better decision-making for maintenance management.

Turnstile and ESD Access Monitoring System

ESD Monitoring System validates and records RF Badge and electro static discharge result of all personnel’s (employee, customers, contractors and suppliers) footwear and wrist strap devices in turnstile approach. The turnstile will open once employee is allowed to a specific area at the same time if PASSED the ESD checking based on defined acceptable range.

Auto Data Transfer System

The Auto Data Transfer system is designed to automatically collect, transmit, and store data between devices, equipment, or software platforms without manual intervention. It ensures accurate, real-time data transfer for monitoring, reporting, and analysis while minimizing human error and improving operational efficiency.

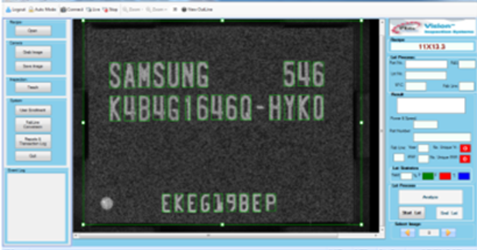

Vision Integration System

The Vision Integration System is a customizable solution that combines automated visual inspection with tailored lot tracking and validation algorithms. It captures and analyzes lot details based on customer-specific requirements, ensuring precise verification, defect detection, and reliable data validation to support quality assurance and traceability in production.

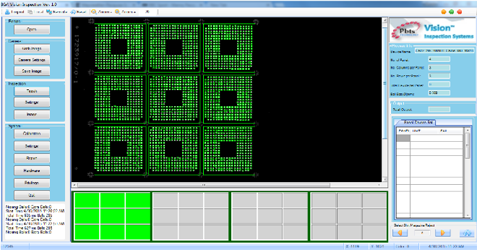

Ball Grid Array (BGA) Inspection System

The Ball Grid Array (BGA) Inspection System is integrated into machine operations to ensure accurate and reliable inspection of BGA components. The system automatically checks for missing balls, extra balls, oversized or undersized ball diameters, and ball pitch alignment. It provides a clear PASS/FAIL result based on the defined inspection criteria, supporting consistent quality control in production.

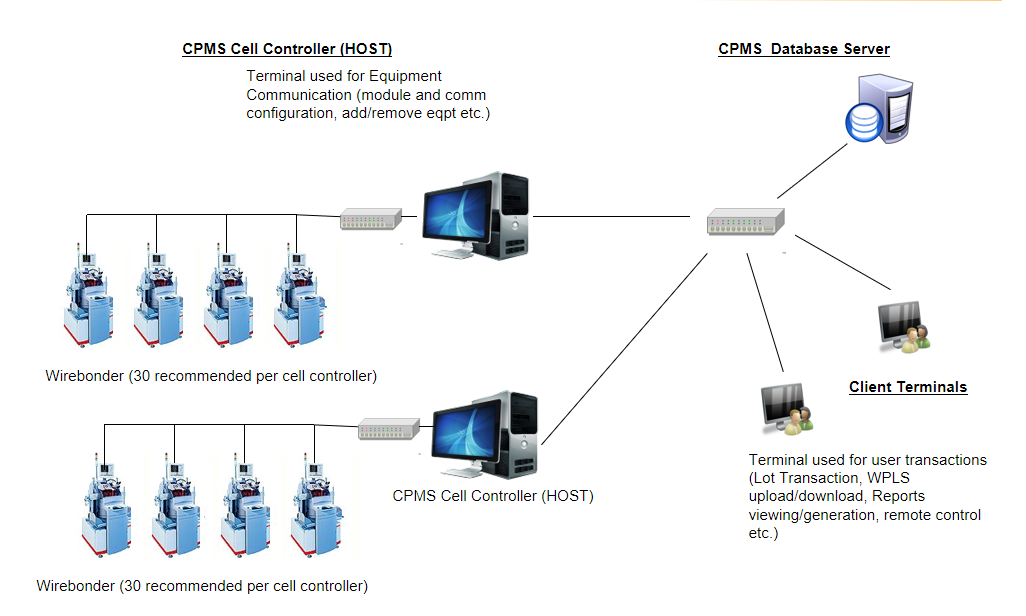

Centralized Productivity Monitoring

Centralized Productivity Monitoring System is a remote intelligent computer, controlling all the equipments that linked to it provided that the equipment is GEM Compliant. Most of the equipments features are automatically controlled by a Equipment Controller which includes Recipe Management, Statistic Management, Alarm Management, Report Management.